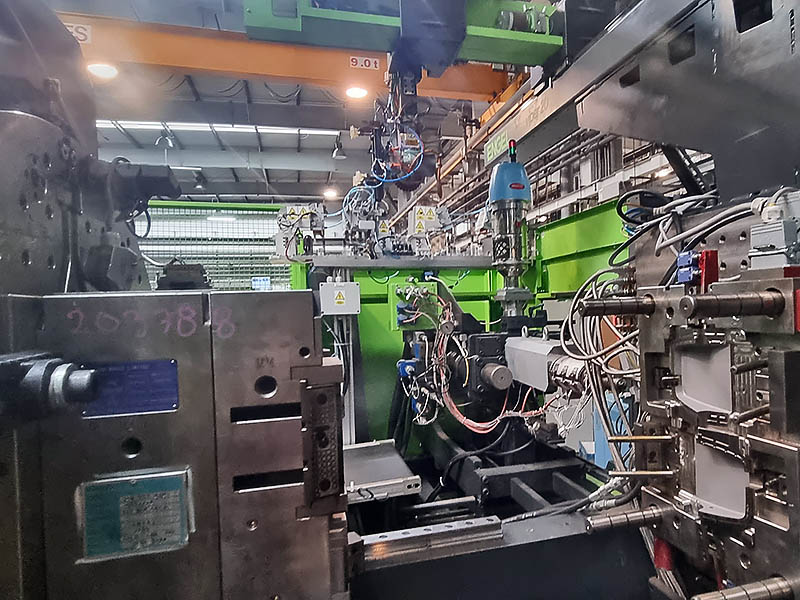

Our machinery park includes 40 state-of-the-art injection molding machines from 50 to 1,300 tons, including electric, two-component, gas injection and blow molding machines, laboratory, assembly and decorative equipment.

Injection molding machines:

- Arburg 50 Tons

- Demag 50 Tons (3)

- Demag 80 Tons (2)

- Krauss Maffei 80 Tons

- Demag 100 Tons

- Demag 110 Tons

- Demag 120 Tons (2)

- Demag 130 Tons (2)

- Krauss Maffei 130 Ton (2),

- Demag 160 Ton,

- Krauss Maffei 200 Tons

- Krauss Maffei 250 Tons (2)

- Demag 280 Tons

| - Toyo-Hitachi 280 Tons

- Krauss Maffei 300 Tons

- Demag 350 Tons

- Toyo-Hitachi 350 Tons

- Krauss Maffei 420 Tons

- Demag 500 Tons

- Toyo-Hitachi 550 Tons

- Krauss Maffei 575 Tons

- Demag 650 Tons

- Toyo-Hitachi 680 Tons (2)

- Demag 800 Tons

- Demag 1100 Tons,

- Krauss Maffei 1300 Tons.

|

Machines for two-component injection molding:

- Demag 110 with rotary table and integrated second vertical unit

- Krauss Maffei 575 with rotary table and integrated second side unit.

Blow molding machines:

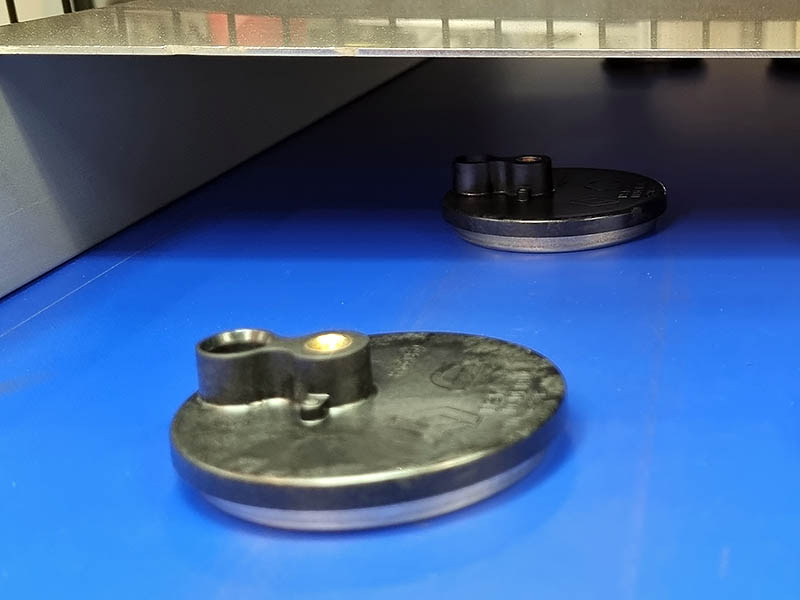

Mold handling equipment for gas assisted injection:

- Nitrogen generator

- Nitrogen compressor (2)

- Monomodule (4)

- Remote control device (4).

Laboratory equipment:

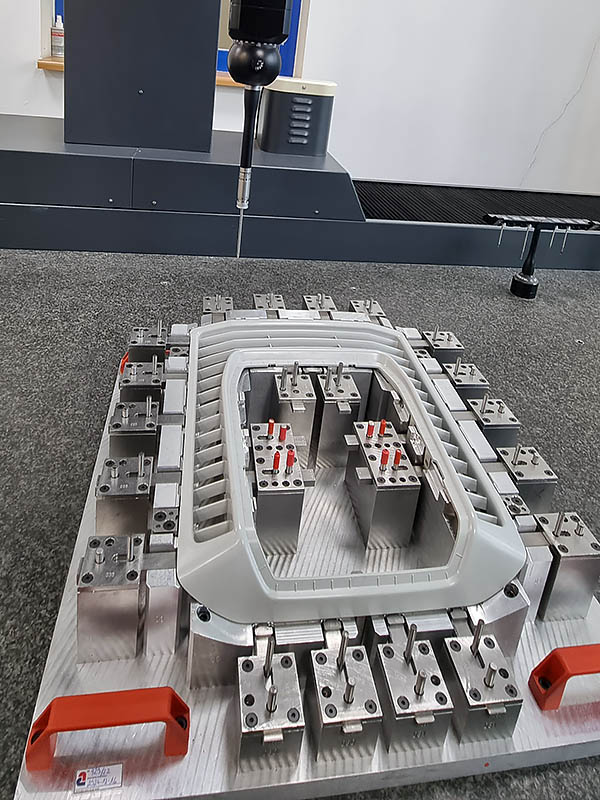

- 3D measuring machine Wenzel LH54

- 3D measuring machine Wenzel LH108

- Climatic chamber

- Fume hood

- Flammability test chamber

- Melt Index Tester

- Scratch Tester

- Gauges

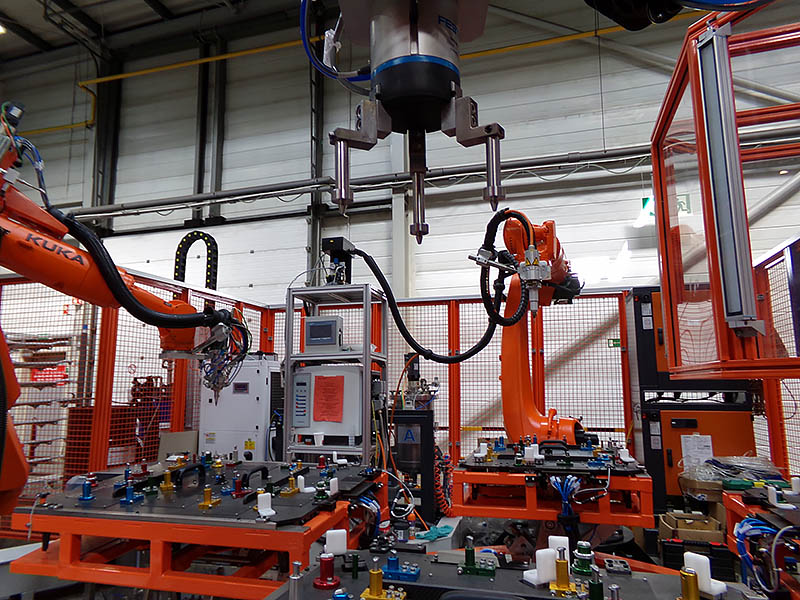

Assembly equipment:

- Ultrasonic welding machines

- Thermal welding machines

- Assembly and inspection machines.

Decorative devices:

- Tamporint

- Screen printing

- Painting stations.

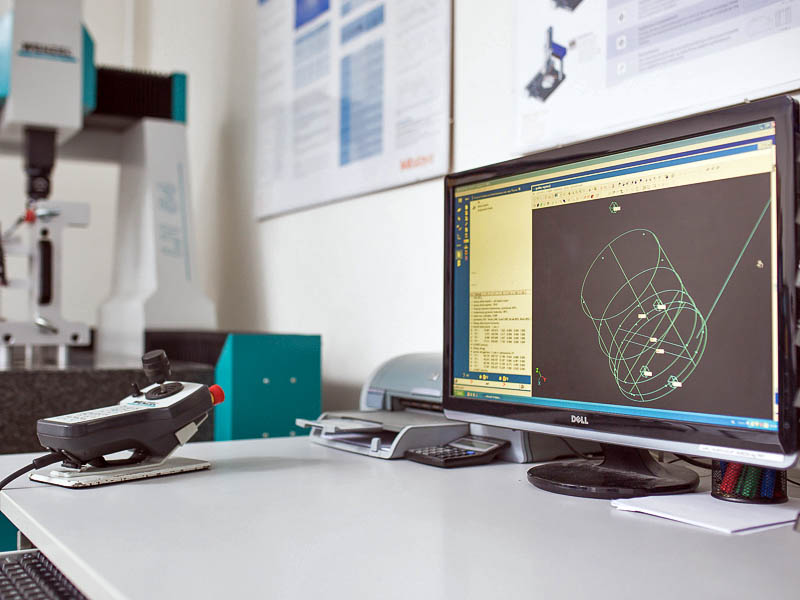

Design software:

- CATIA V5R19

- Autodesk MouldFlow

- Autodesk Inventor Professional 2012.